In the past 1½ years, a lot has been said about how these two approaches relate to each other. By the middle of 2015, the discussion was so heated that technical people became frustrated that the discussion was not based on solid, technical facts. More light than heat was required! By then, too, an increasing number of companies were active in both communities; it became even more important to understand the technical issues and reduce market confusion.

In the fall of 2015, people from companies involved in both organizations decided to cut through the fog and get to the bottom of it. Let’s get a handful of technical people from both groups to compare notes and see if common ground could be found. Switzerland was jokingly chosen as a neutral place, and representatives from Bosch, Cisco, IIC, Pepperl + Fuchs, SAP, Siemens, Steinbeis Institute and ThingsWise came to an informal hands on meeting in Zürich to discuss technical issues only.

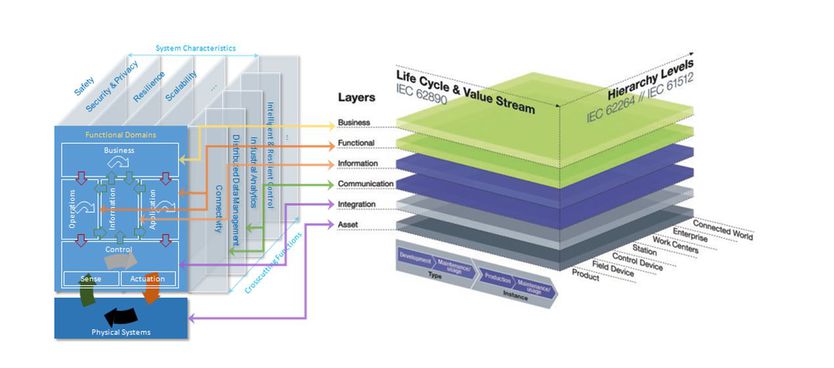

As is typical for technical people, after a short exchange about how each organization works, we stepped into an open technical discussion. Colleagues from Plattform Industrie 4.0 explained details about their Reference Architecture Model Industrie 4.0 (RAMI 4.0), related standards and what an Industrie 4.0 component looks like. The component is a shell to connect industrial things to the internet. They explained the assembly hierarchy levels common in manufacturing, not seen in, say, process control or telecommunications.

Colleagues from the IIC outlined the Industrial Internet Reference Architecture (IIRA) with a focus on its four viewpoints (business, usage, functional and implementation—adopted from ISO/IEC/IEEE 42010:2011), key system characteristics and their assurance (especially safety, security and resilience) and the several cross-cutting concerns (such as connectivity, data management, industrial analytics, and interoperability).

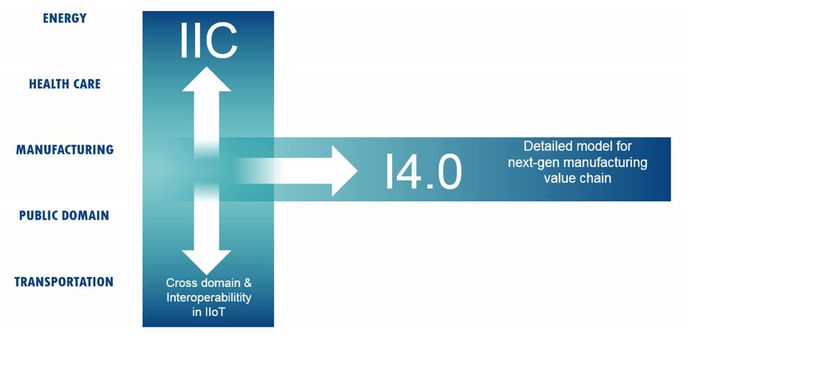

We began looking at the technical issues. With RAMI 4.0, Industrie 4.0 focuses on manufacturing in depth; IIRA crosses multiple application domains. Industry as a whole needs to be able to work across domains; manufactured goods are one of those domains. As a concrete example, an automobile containing multiple manufactured components needs to work together as a single unit (all manufacturing so far). But when it’s parked at home charging its batteries overnight, it needs to be able to connect to the smart grid. Clearly, these domains must interoperate. Equally, on the road, the connected car has to be able to talk to other cars, traffic lights, the road and the rest. Again, these domains need to work together, even though specialized manufacturing approaches were needed to create the car in the first place.

© Robert Bosch GmbH

Then we dived a little deeper. How exactly would that happen? We noted right away that some names were the same (the business viewpoint, for example), while others that had different names (connectivity vs. communication) yet appeared to be the same thing. We realized it would take time and real work to examine the definitions and content to determine whether they were the same or not. Or more likely, mostly the same, with differences around the edges.

© Robert Bosch GmbH

There are broader issues too. Should the concept behind the Industrie 4.0 component be explicit in the IIRA? Should Industrie 4.0 break apart the functional viewpoint to the level of detail that is present in the IIRA? Obviously, answers to those questions demand a much deeper common understanding. There was a strong willingness and desire to work together to reduce arbitrary differences and fragmentation.

Interoperability means that we must influence global standards. It would be inefficient for both organizations to drive the same needs into the same standardization organizations. And it would be self-defeating if we were to drive different requirements into those organizations. We concluded we should formulate requirements for standardization bodies together.

That said, we also realized a merger of the two architectures was both impractical and undesirable. Each domain in the Industrial Internet has its own special needs. Industrie 4.0 focuses on manufacturing; IIC is concerned about integration across domains.

Because the two approaches are complementary and can enhance each other, we agreed that we should recommend to our respective boards that we extend our cooperation. We should start a regular technical exchange, identify mappings, differences and enhancements on both sides, discuss common testing, and of course work together for the benefit of interoperability of systems from the different domains.

Our first meeting was a great pleasure as we came to understand the other’s point of view more clearly. When technical people meet, they can make good headway and come up with specific proposals to work together. (That input has been an important part of how we came to this announcement. We are looking forward to working on this!